Mold Management System, MMS

to help the die shop production personnel keep track of the tooling and status in an organized manner

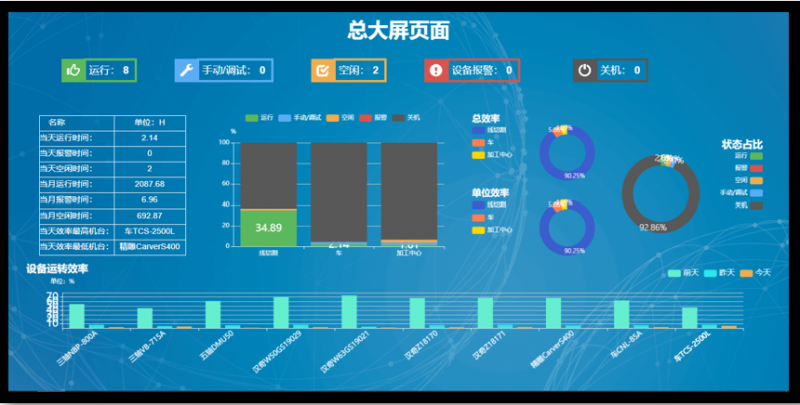

Real-time master the enterprise on-site status, detailed and clear information, reduce delay, and rapid respond to customer inquiries

For each die & components production, detail information will be centrally located: SOP, planning & scheduling, raw materials, dynamic information, first trial performance, et

Accurately track cumulative production cycles, remaining die life, etc

With good preventive maintenance, repair, services, the die will always in a “ready to use” state to prevent unexpected downtime and excessive scrap

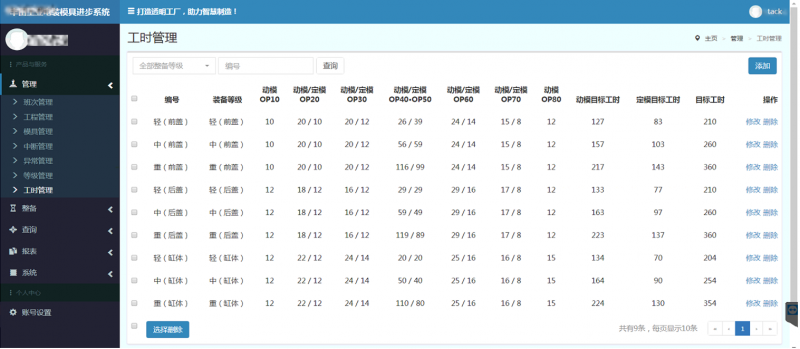

Work Cycle Time

Through the use of mold QR, manage and track status

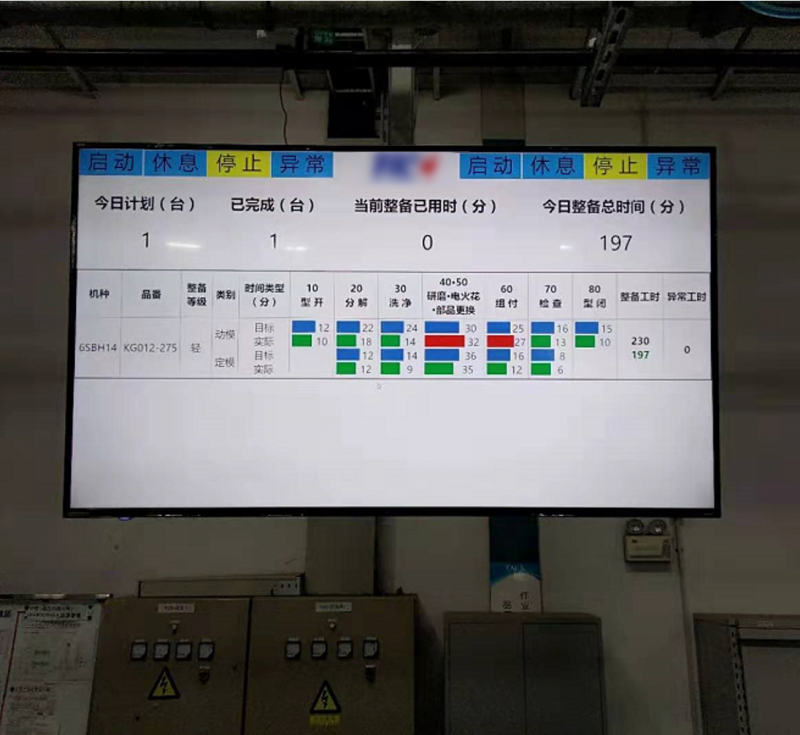

Kanban management (working hours, abnormal information, etc.)

Anomaly management and query

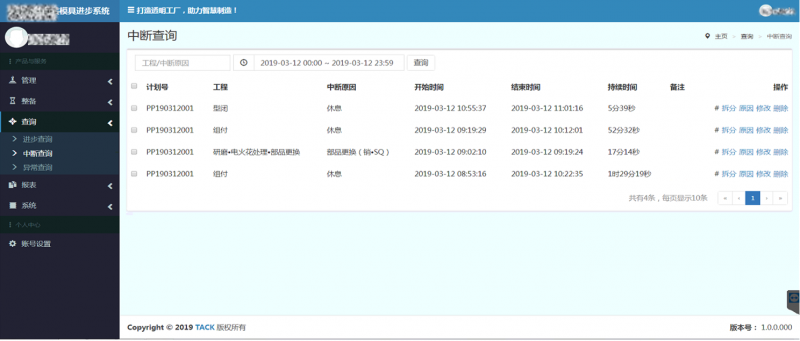

Interrupted management and query

Automatic shift reporting and report generation

Standard work cycle time for each level & each OP

Standard operation instruction management

Preparation

Mold scanning, station preparation status, interrupted handling, anomaly handling and other operations

Interrupted Query

Mold servicing interrupted data query, including interrupt reason, duration, etc.

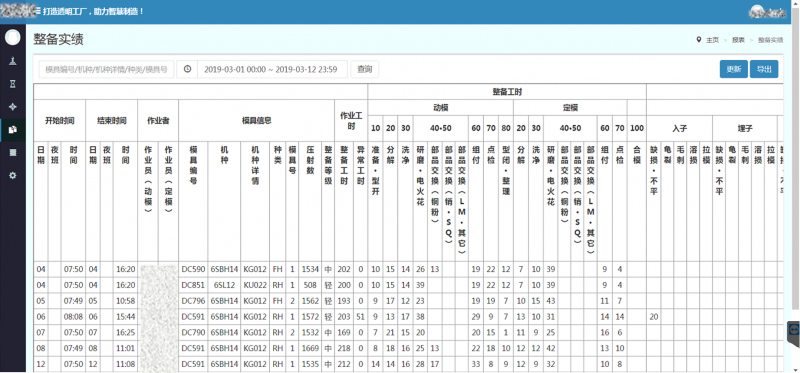

Actual Manhours Reports

Automatic shift report: time, date, operator, mold information, working hours, abnormal working hours and other data

Consolidated Report

The comprehensive monthly report search according to the station, mold and time

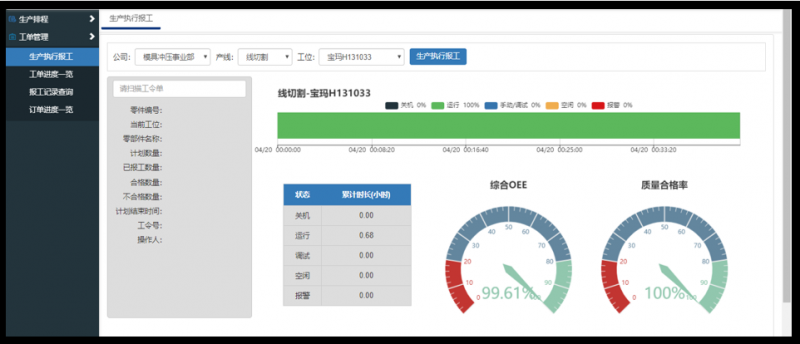

Die Kanban

Die Kanban display the current preparation time, abnormal conditions, plan vs actual work cycle time and other information.